About This Project

Farming animals for leather is a water, chemical, and energy-intensive process. Fungal "leather" could help address sustainability problems when farming and using animal leathers, as they can have similar structures to animal skins and perform physically like leathers. The research requires cross-linking fungal mycelium onto a bacterial cellulose matrix to improve fungal-mat flexibility, strength, and leather feel. We aim to refine protocols for these fungal-bacterial biocomposites.

Ask the Scientists

Join The DiscussionWhat is the context of this research?

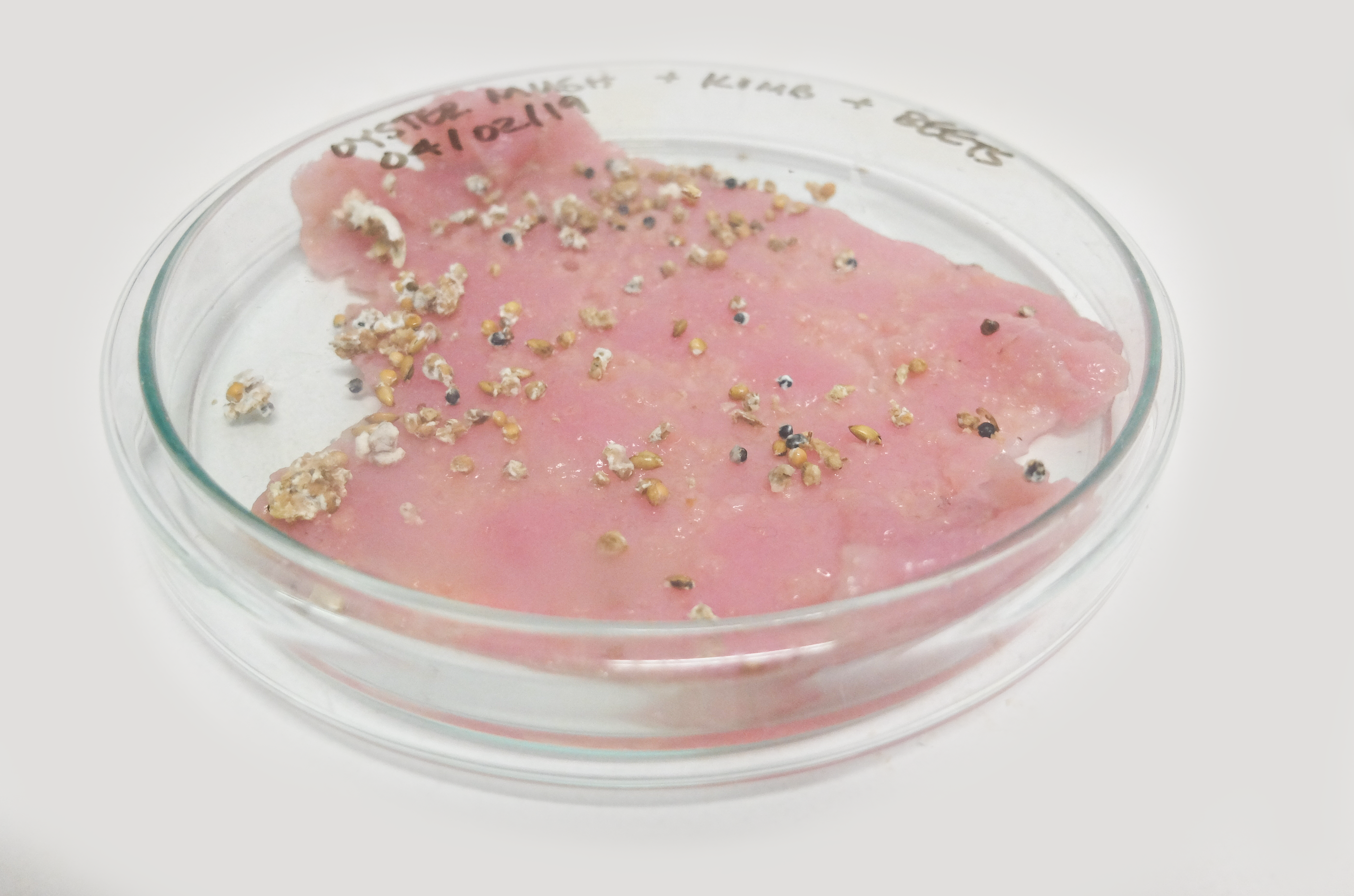

Current fungal sheet materials are composites of mycelium and lignocellulose. The mechanical properties remain suboptimal, among other reasons, due to the weak internal bonds between the hyphae and the natural fibers. We have been testing the complementary properties of mycelium grown on bacterial cellulose.

Our experiments show mycelium and bacterial cellulose form a multilayer structure grown into pliable and resistant sheets. This composite allows the mycelium sheet more flexibility and gives kombucha a softer surface and added resistance to wear and tear. Mycelium also provides the bacterial cellulose membrane hydrophobicity, stabilizing the state of the dehydrated material in humid conditions.

What is the significance of this project?

Animal leathers are energy, water, land, and chemical-intensive materials ubiquitous to the textile, automotive, furniture, and fashion industries. Leather is one of our most impactful materials regarding climate change, and alternatives are equally unsustainable - the use of PU or PVC vegan leathers is just as detrimental to our planet.

While many companies have inspired us with the potential of mycelium and bacterial cellulose as circular textile alternatives for leathers, not much research has been made on mycelium's and bacterial cellulose's hybridization to reinforce mycelium's micro-structures in mycelial sheets for textile production.

Mycelial alternatives for animal protein products like leather could have the most impact for the textile industry to make sustainable changes.

What are the goals of the project?

Our goal is to collect data on the hybridization of fungal-bacterial composite sheets to improve the physical properties of mycelium-based leather-like materials and refine and document protocols and required finishing processes for its stabilization.

We propose to do this by examining the cross-linking of bacterial cellulose grown in a waste sugar feedstock fermentation and inoculating the produced membrane with mycelium. After the growth process finalizes, further cross-linking with biopolymers like chitosan and plasticizers can be added to improve the durability and flexibility of the final material.

Our aim is also to document and analyze our impacts on a micro-scale on water, energy, biodegradability, biodiversity, bioaccumulation, and waste.

Budget

The myco-skin is in the R&D and prototyping stage. We have invested in the materials, machine use, and personal work hours put into the prototype of the project. Currently, we are working on funding by applying for open calls and collaborations with makers and design studios.

This funding will allow us the necessary tools, equipment, material testing facilities, and collaborators not only to reproduce the method of the bacterial cellulose/mycelium composite but to study and test the properties of the material, impacts on the environment trou degradation, possibilities of its use for fabrication and alternative applications for textile finishes.

Our primary work will focus on material preparation, experiment setup, observation, and data collection.

Our staff fees will cover an honorarium for the collaborators of $500 each; the project will require a minimum of 5-10 hours /week of lab work. Monitoring, documenting, data analysis, and maintenance will not be included.

Endorsed by

Project Timeline

Project Timeline

Ideally, We could conduct this research over six months, creating a report of material specs, fabrication, and potential uses.

The first few months would involve culturing and growing mycelium strains on bacterial cellulose to determine the best possible properties and outcomes and exploring additives and drying techniques.

We would devote the last months to testing the material properties, enhance the composite membrane and test as additives or finishing agents for textiles.

Jul 29, 2022

Project Launched

Aug 15, 2022

culturing mycelium strains

Aug 15, 2022

growing bacterial cellulose membranes

Sep 14, 2022

inoculate membranes w. various strains

Sep 30, 2022

incubation period

Meet the Team

Team Bio

International collective of artists, designers, and researchers. We aim to engage in radical connections with the non-human through bio-centric practices.

As independent researchers and designers, developing a variety of biomaterial projects has given our team a solid background in allocating resources, time, machines, materials, and any outsourced work required when creating my projects.

Our team creates commissioned works, open call projects, and educational programs.

Catherine Euale

I am a multimedia bio-artist, social and environmental activist, costume designer and storyteller.

My work centers around deepening our relationships with more than human worlds and challenges the need to use materials and methods that are non-compatible with living systems.

As an environmental, social, and animal rights activist, I believe that an approach to learning from nature, traditional crafters, and indigenous communities can lead us on a more holistic path toward a resilient future that is collaborative with living systems.

My process for design is based on a planet's first philosophy, which puts people, the planet, and biodiversity before production. This practice allows the research and development of the material to guide the design process. My work meets at the intersection of science and art practices.

As a founding collaborator of S-BIOTICA studio, owned and operated by Jessica Dias, I assisted in creating a hub for biodesign and experimentation in Barcelona. I have experience in wet lab experimentation, mycology, prototyping, and machine making, maintaining proper documentation while also building a fundamental working knowledge of scientific methods.

Additional Information

Mycelium-bacterial cellulose composite untreated surface hydrophobicity

Mycelium-bacterial cellulose composite untreated surface hydrophobicityInstructional video @Fungi Academy

Mechanical characteristics of bacterial cellulose-reinforced mycelium composite materials

Multi-Organism Composites: Combined Growth Potential of Mycelium and Bacterial Cellulose

Advanced Materials From Fungal Mycelium: Fabrication and Tuning of Physical Properties

Project Backers

- 11Backers

- 100%Funded

- $3,560Total Donations

- $323.64Average Donation